CNC Plasma Gas Cutting Machine - Ritik Engineers

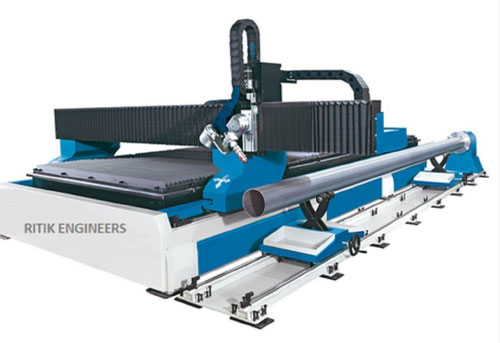

The CNC Plasma Gas Cutting Machine from Ritik Engineers is a state-of-the-art cutting system designed for high-precision thermal cutting of metals using plasma and gas. It integrates advanced CNC control with plasma and oxy-fuel technologies, providing fast, accurate, and efficient cutting for a wide range of materials. The system offers high flexibility, making it ideal for cutting ferrous and non-ferrous metals with varying thicknesses and complexities.

Advantages of Ritik Engineers' CNC Plasma Gas Cutting Machines

- High Precision: CNC control ensures accurate cuts with minimal kerf width for superior edge quality.

- Fast Cutting: Plasma cutting speeds up production compared to traditional methods.

- Versatile: Cuts various metals like mild steel, stainless steel, and aluminum at different thicknesses.

- Cost-Effective: Plasma cutting is more economical than laser cutting for industrial use.

- Minimal HAZ: Less thermal distortion, ideal for materials requiring minimal heat exposure.

- Improved Safety: CNC control reduces operator exposure to high-temperature cutting areas.

- Easy Integration: Seamlessly fits into existing production workflows.

Applications

- Heavy Manufacturing: Ideal for industries that require the cutting of thick metal plates, such as steel mills and shipbuilding.

- Structural Fabrication: Used extensively in the fabrication of bridges, buildings, and other large infrastructure projects.

- Automotive: Cutting and shaping of metal parts for automotive manufacturing.

- Construction: Precision cutting for structural steel components used in construction projects.

- Aerospace: Used for cutting intricate aerospace components and structural parts.

- Oil and Gas: Cutting of large pipes and metal parts in the energy and oil industry.

- Art and Design: Ideal for creating artistic metal designs, signs, and decorative elements.

Multi Torch CNC Plasma Cutting Machine

RE 1325P

| Specifications | |

|---|---|

| Model | RE 1325P |

| X-axis Travel / Y-axis Travel / Z-axis Travel | 1250 X 2500 X 200 mm (Customize options) |

| Plasma Power | 65A, 100A, 105A, 120A 160A, 200A |

| Motor for X, Y, and Z | Stepper motor / AC Servo motor |

| Working Voltage | 380V/50HZ/60HZ,3PH. Option: 220V,3PH |

| Max. Working Speed | 25000/min |

CNC Plasma Cutting Machine

With Rotary

| Specifications | |

|---|---|

| X, Y & Z Axis Travel | 1250 X 2500 X 200 mm (Customize options) |

| Plasma Power | 65A, 100A, 105A, 120A, 160A, 200A |

| Rotary Axis (option) | 200 mm (diameter) 2500 mm |

| Motor for X, Y, and Z | Stepper motor / AC Servo motor |

| Working Voltage | 380V/50HZ/60HZ,3PH. Option: 220V,3PH |

| Max. working Speed | 25000/min |

CNC Gantry Type Plasma

Cutting Machine

| Specifications | |

|---|---|

| X-axis Travel / Y-axis Travel / Z-axis Travel | 1250 X 2500 X 200 mm (Customize options) |

| Plasma Power | 65A, 100A, 105A, 120A, 160A, 200A |

| Motor for X, Y, and Z | Stepper motor / AC Servo motor |

| Working Voltage | 380V/50HZ/60HZ, 3PH. Option: 220V,3PH |

| Max. Working Speed | Max. Working Speed |

CNC Portable Plasma

Cutting Machine

| Specifications | |

|---|---|

| X-axis Travel / Y-axis Travel / Z-axis Travel | 1200 X 2500 X 150 mm (Customizable options available) |

| Plasma Power | 40A, 60A, 80A, 100A, 120A |

| Motor for X, Y, and Z | Stepper motor / AC Servo motor |

| Working Voltage | 220V/50HZ/60HZ, 1PH. Option: 380V, 3PH |

| Max. Working Speed | 8000 mm/min |

| Cutting Thickness | Up to 25 mm (depending on plasma power) |

| Cutting Accuracy | ±0.5 mm |

| Cutting Material | Steel, Stainless Steel, Aluminum, Copper, and other metals |